Precision Machining Services | High-Accuracy Manufacturing Solutions – Incresol

Discover why precision machining services are critical in aerospace, automotive, and medical manufacturing. Learn how Incresol ensures accuracy, quality, and cost efficiency.

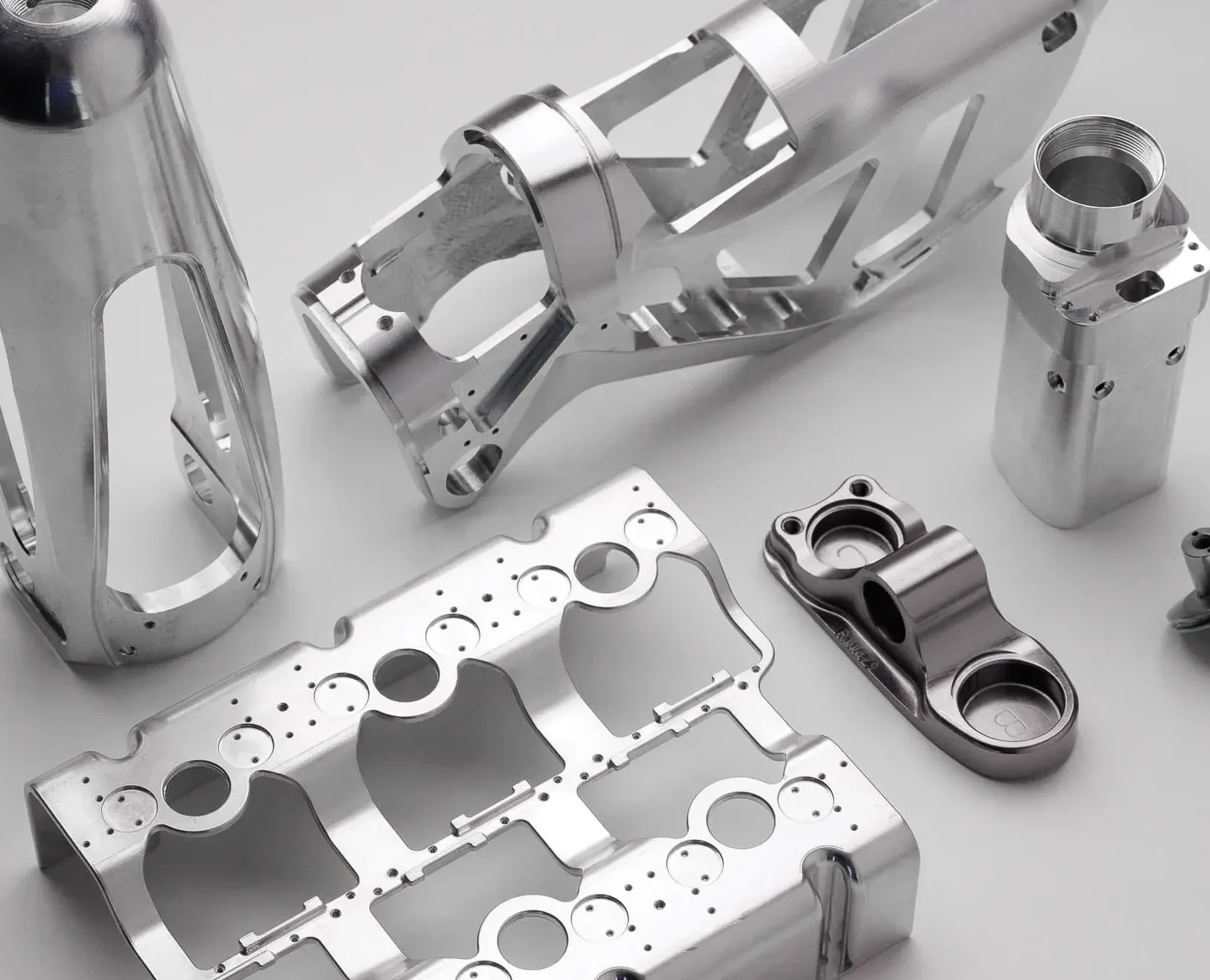

In today’s competitive manufacturing landscape, accuracy is everything. From aerospace components that must withstand extreme conditions to medical devices where precision can save lives, every millimeter matters. This is why precision machining services have become the backbone of modern product development.

At Incresol Engineering Solutions, we provide high-quality CNC machining, sheet metal fabrication, and custom tooling that ensure products meet the strictest tolerances while staying cost-effective.

Precision is not a luxury in manufacturing—it’s the foundation of reliability and trust.”

What Is Precision Machining?

Precision machining is the process of cutting, shaping, and finishing materials into exact specifications using advanced tools like CNC machines, milling, drilling, and grinding equipment.

Unlike standard machining, precision machining:

Achieves tight tolerances down to microns

Minimizes errors in high-volume production

Ensures interchangeability and repeatability across parts

This makes it ideal for industries where quality and safety cannot be compromised.

Key Benefits of Precision Machining Services

1. Unmatched Accuracy

High-precision tools ensure parts meet exact design specifications—critical for aerospace, defense, and medical industries.

2. Consistency in Mass Production

With CNC automation, manufacturers achieve the same quality output across thousands of components.

3. Reduced Waste & Costs

Efficient machining leads to less material waste, lowering overall manufacturing costs.

4. Design Flexibility

Complex geometries and custom designs are possible with advanced machining and CAD/CAM integration.

5. Faster Turnaround

Automated processes reduce lead time, helping OEMs and Tier 1s bring products to market faster.

Applications of Precision Machining

Aerospace & Defense – Aircraft components, engine parts, and satellite systems

Medical Devices – Surgical instruments, implants, MRI/CT scanner parts

Automotive & EVs – Engine parts, drive systems, EV battery enclosures

Industrial Equipment – Gears, fasteners, hydraulic systems

Renewable Energy – Turbine components, solar mounting hardware

Incresol’s Precision Machining Capabilities

At Incresol Engineering Solutions, we combine expertise with technology to deliver:

CNC Machining – Milling, turning, drilling, and grinding with micron-level precision

Sheet Metal Fabrication – Cutting, bending, and welding custom enclosures and assemblies

Tooling, Jigs & Fixtures – In-house design and manufacturing for high-volume production

CAD/CAM Integration – Design-to-production with simulation-driven validation

Quality Assurance – 100% inspection, Hi-Pot testing, and compliance with industry standards

Precision machining is the key to modern manufacturing. From aerospace to medical devices, industries rely on exact tolerances and high-quality parts to stay competitive.

At Incresol, we deliver precision machining services that combine accuracy, speed, and cost-effectiveness, ensuring your products are built to last.

OUR PRODUCTS

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.